PT Blog

In this section, we share some insights on our stay cable production. Also commonly known as bridge cable, stay cable applications are getting more popular for big span bridges.

Bridge designers are getting bolder in their dynamic demands and one of the common approach is to design bridges with stay cable. Not only can they overcome engineering difficulties, cable stayed bridge also add the aesthetic effects to the bridge construction. And very often, mega cable stayed bridges turned out to be outstanding landmarks attracting scores of visitors.

In this post, we show some production processes on our pre-fabricated stay cable productions. TMG Stay Cable produced with 7-wire high tensile steel cable (PC strand) made up about 80% of all our stay cable production. And of these, more than 50% are pre-fabricated stay cables.

Pre-fabricated stay cable offers a fast and efficient solution to small and medium-size cable stayed bridges. It eliminates the requirement for heavy lifting crane and machinery. It also reduces the total manpower and on-deck carbon footprint. And the most attractive factor is the fast turn-around time as compared to on-site installation stay cable. There is no requirement for on-site strand-by-strand prestressing or post tensioning work.

Pre-fabricated stay cable manufactured under factory conditions, is also more consistent with quality, waterproofing, finishing and performance.

Production of Post Tensioning Accessories (Anchor Head & Wedge)

This simple video captures some process in our production of post tensioning accessories, namely Anchor Head and Wedge.

Anchor Head (also commonly known as Wedge Plate) is an important part of the post tensioning system. It works in tandem with the Wedge that holds the individual tensile element. The prestressing load is then transfer to the Bearing Plate. For some small tendon sizes, this prestressing force can be transferred directly to the structure without the need of Bearing Plate.

In the case of some mono anchorage system, the Wedge will hold an individual tensile element directly to the Bearing Plate.

Anchor Head and Wedge is subjected to Static Load and Fatigue (Reliability) Test. Hence its design and production quality control is of paramount importance.

Static Load Test requires the Anchor Head and Wedge to hold to a specific percentage (>95%) of the tensile element ultimate strength with a minimum elongation (>2%), with without premature failure of anchorage components, without undue deformations in the components, and without disproportionate relative movements between tensile elements and anchorage components.

As for Fatigue Test, the Anchor Head and Wedge have to go through 2 million cycles of fatigue loads (dynamic strength, 80MPa) without exceeding a specified percentage loss of tensile element cross section (<5%).

We hope this video provides some insight of our production process and gives our operators a better understanding of our commitment to quality control.

Customized 100 metric ton Stressing Jack

In July 2015, we started to deliver a series of customized Stressing Jack to some precast concrete operators. This 100 metric ton Stressing Jack works on a 200mm length stroke and it is able to perform simultaneous stressing job on 4 PC strand spaced 50mm apart.

TMG successfully helped the operators to reduce up to 75% of their mapower cost and also increased the production cycle time. And this is a tremendous improvement on the overall work productivity and efficiency.

As TMG is specialized in all sorts of customization work, we are constantly working on more innovative and groundbreaking products. This will inevitably bring values and reduction in operation cost for our users, both on prestressing and post tensioning jobs.

The development of technology brought us many conveniences and also altered our tradional ways of running businesses. And TMG believes that by embracing and implementing appropriate adaptation with technology, we can remain relevant and also ahead of the changes in the prestressed concrete industry.

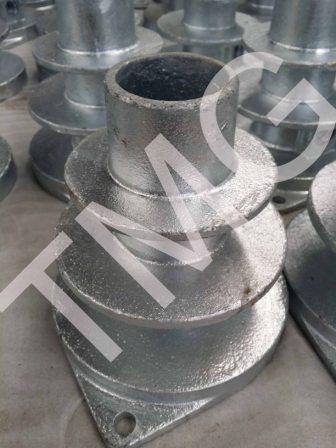

Bearing Plate is a very important element in a post tensioning system. It serve the purpose of transfering prestressing force derived from the tendon (tensile element, eg. PC strand) to the concrete. And it is precisely in this, that explains what we want to achieve in prestressed concrete structures, and thus we take a special interest on the Bearing Plate.

In our earlier blog post we shared on the testing we conducted on ‘Load Transfer and Static Load Test of Anchors in accordance to European Technical Approval (ETAG 013)’, we posted some photographs of Bearing Plate casted into concrete blocks for Load Transfer Test. Well, this is to test the ultimate load bearing capability of the Bearing Plate (by means of a Stressing Jack) under a real-life situation. As ETAG 013 specification clearly states under Load Transfer to the Structure; “Post Tensioning systems shall be able to transfer a specified percentage of the tensile element ultimate strength from the anchorage into the concrete structure, of a defined strength class of concrete, without undue cracking of the structure, and at deformations which stabilise within a given time frame”.

However, we are not going in-depth on this test procedure and result. Rather we are taking an interest on the manufacturing of the Bearing Plate. Bearing Plate is generally manufactured with ductile iron (eg, ASTM A536, Grade 80-55-06) or grey iron (eg, HT200, GB/T9439-2010), casted in a steel foundry. There are numerous ways in the production of Bearing Plate. From an automatic production line (eg, DISA) to a brick & mottar method of using moulds, very much like how we produce precast concrete products.

We take a particular interest in a method we are familiar with, and that is, the usage of polyfoam to bring our Bearing Plate to life!

The polyfoam is produced to the exact same shape and size as the actual Bearing Plate. And then a layer of clay is coated over the polyfoam to form an ‘temporary’ mould over it. Molten iron is then poured into this temporary mould through a small opening, and the polyfoam inside will then be burnt away. With the disappearance of the polyfoam, the molten iron will then filled up the temporary mould. Once the molten iron cools down and harden, the removal of the exterior clay will then give us the Bearing Plate we wanted.

We posted some photographs of our Bearing Plate production process and we hope this will provide some insights of our daily production activities.

Small State = Small Company, Successful Nation = Successful Company?

This interesting interview with the Deputy Prime Minister & Minister for Finance of The Republic of Singapore, Mr Tharman Shanmugaratnam, on the 45th St. Gallen Symposium, Switzerland, caught our attention. It is unprecedented that we post a topic on our blog that has no direct connection to the daily activities that we are in.

In this interview, Mr Tharman spoke about the realities and challenges small countries faced. And also how, with limited resources and a small natural market, coupled with a positive attitude of mind, can transform a small country like Singapore, to a successful and prosperous nation, in one generation. We were particularly impressed by the way Mr Tharman conveyed on how we took advantage of disadvantage and how we converted permanent disadvantage to continuing advantage. In this 48 minutes video, many tough and hard-hitting questions were posted to Mr Tharman. And he narrated at length the difficulties and constantly evolving policies to make things work in a digital-age, with unconventional ways, for now and for the future. Learning the path others had navigated and tailoring these experiences to our society to avoid pitfalls.

One can take a few steps back and seriously ponder. Can small company learn from the way Mr Tharman had explained to us? The answer is no other than “YES”!

TMG is a growing post tensioning company on the international arena, has a lot of learn from such a mindset. And it is precisely our presence on the international market, we have to constantly stay ahead of the competition in order to remain relevant.

This video share with us on “the mentality we must have when we have nothing, and the attitude we must possess when we have everything”!

Enjoy the interview…….

Steel Corrugated Duct for Bonded PT

Duct is an important element for bonded post tensioning work. It is essential as it creates a void for the tendon or tensile element. By and large, steel corrugated duct provides the most economical solution to bonded post tensioning work.

Steel corrugated duct are manufactured from a long galvanized strip of steel, normally in the range of 0.25 – 0.40mm in thickness and can be 30 – 80mm in width. It depends on the type of duct forming machine used. These strips are then pressed into a corrugated form before they are fed into a turning wheel to make the edges interlock, and forming into a pipe. And in post tensioning terms, we call this pipe a ‘duct’. And duct can come in 2 types of shapes, round and flat. A steel corrugated flat duct is pressed into shape from a steel corrugated round duct and it is generally used for slab anchorage (not limited).

Duct plays a critical role in providing a corrosion protection environment to the tensile element or tendon (eg. PC Strand). And steel corrugated duct offers excellent bonding behaviour to tendon grout and also the concrete around it. And it is precisely because the duct is a protection to the tendon, its quality is paramount.

Due to the way the steel corrugated duct is produced, bad quality duct can cause huge problems like ‘bleeding’ during the construction process. Most of the time, it is the bad interlocking of the edges between adjacent strips that causes the duct to collapse under the weight of the concrete. This results the concrete to leak into the duct (term ‘bleeding’) and bond with the tendon even before stressing commence.

Operators are well aware of the repercussion bleeding can cause. During stressing, it causes the tendon elongation to fall under the required length even though the stressing jack and pump had worked to its required load. To sum it up, we call this prestressing lost (due to frictional effect). This is a situation everybody wants to avoid.

Duct is also available in plastic form, generally made of polyethylene / polypropylene material. Plastic duct has lesser bleeding issue and it is more commonly found in corrosive environment like waste water treatment tanks, acid tanks, silos etc. However steel corrugated duct is still the preferred choice for providing a homogenous environment to prestressed concrete structure, primarily due to its excellent bonding characteristic. And in some countries, plastic duct are barred because of fire safety regulation. This is because the burning of plastic during a fire hazard can emit poisonous gases and it is harmful to humans.

TMG visited a few project sites and with the blessing of the main contractors, we managed to film the process of steel corrugated duct production. The source of the duct forming machine remains unknown.

Anchor Head, Bearing Plate & Wedge Shipment

Recently, TMG delivered 8 containers of Anchor Head, Bearing Plate and Wedge for a project in South Asia. This project uses a mixture of slab anchors of 4 and 5 strand, and multistrand anchors of 3 to 19 strand. All supplied anchors are for 15.20mm strand size. As post tensioning is becoming more popular in developing countries, we are seeing an upward trend in prestressed concrete structure design.

Just 20 years ago, prestressing seems to be a taboo in these developing countries. Despite the fact that post tensioning can bring a lot of tangile benefits to the whole structure, developers and contractors are conservative in accepting the advantages that it can bring. Many were septical and conventional in the way they viewed civil construction. The growth and popularity of internet helped and transformed the development of post tensioning. With information now easily available over the internet, developers and consultants are more well informed and have better understanding of post tensioning. This information-age development also accelerated the transformation and acceptance of post tensioning, from an unfamilar technology to a widely accepted one today.

As market demand for post tensioning increases, the surge in post tensioning accessories supplies also effected the cost of carrying out such construction to be more transparent, thus bringing benefits to developers and contractors. Products like PC strand, Stressing Equipment (Stressing Jack, Pump, Grouting Machine etc), post tensioning accessories (Anchor Head, Bearing Plate, Wedge etc) become widely available and can be delivered with short lead-time.

Below are some photographs of TMG Anchor Head (before packaging) in our storage warehouse, ready for shipment.

TMG PC Strand Manufacturing Facilities

PC strand is widely used in prefabricated or precasted concrete elements like hollow core slabs, girders, beams, railway sleepers, foundation piles, poles etc., and also in post tensioning constructions such as bridges, buildings, dams, tanks, silos etc. And also as tendons in bridge cable or stay cable. Its application is far and wide, both for pre-tensioning and post tensioning, bonded and unbonded applications.

TMG is one of the world largest PC strand manufacturer, our Low Relaxation 7-wire PC strand are manufacture with high quality wire rod in a variety of steel grades. In 2014 alone, we produced over 330,000 ton of PC strand and shipped to more than 35 countries around the world.

TMG is capable of producing PC strand with these standards ASTM A416, BS 5896, JIS G3536, AS/NZS 4672.1, EN 10138 etc., with a variety of sizes. Ranging from 9.30mm to 28.60mm in diameter. And all PC strand are delivered in precision wound coils with excellent pay-off properties. Standard coil weight is around 3 tonnes. Special coil weight is also available on request. And anti-rust proofing is also a common practice for coils that requires longer transhipment duration.

Below is a video showing our manufacturing facilities.

TMG has a few manufacturing facilities catering to different types of products. In the video shown, this is the production area for the manufacturing of

1) Post Tensioning accessories

- Anchor Head (1 to 55 strand)

- Wedge (9.53mm to 21.80mm)

2) Stay Cable (Bridge Cable) (up to 151 strand)

3) Stressing Equipments

- Mono Jack (26 ton)

- Stressing Jack (up to 1500 ton)

- Lifting Jack

- Stressing Pump

- Bond Head Machine

- Compression Fitting Machine

TMG’s capabilities in manufacturing, for high-volume products or in high-mix, low-volume post tensioning related products of the highest complexity, together with years of investments in state-of-the-art process and product technology, sets us apart in the post tensioning industry. Our seamless manufacturing system provides us with total control of the whole manufacturing process, promising product of high quality and good cost efficiencies.

With the help of computerized simulation (3D), we are able to achieve quick set-ups for high-volume production as well as optimized utilization for high-mix, low-volume manufacturing environment with quick turn around time.

We understand every customers' unique expectations and requirements. By leveraging on our invaluable wealth of expertise and capabilities, together with a long history of proven record and successful operations in different parts of the world, TMG strives to exceed customers’ expectations and meet the specific challenges.

Cable Stayed Bridge is a kind of bridge formed by the combination of tower and bridge cable, to support the deck of the bridge. Its structure is developed through the load bearing of the tower, tension of the bridge cable and the bending of the deck beam. It can be understood as the bridge cables replacing bridge columns / piers, in a multiple span context. The advantages are

- reduced bridge deck size

- reduced structure height

- reduced overall structure weight

- reduced usage of construction materials

Cable Stayed Bridge can be classified into 3 classes, namely parallel type, fan type and star type. In parallel type, the stay cables are almost parallel and the height of their attachment to the tower is proportional to the distance from the tower to their deck mounting location. As for the fan type, the stay cables are all connected to or pass over the top of the tower. Lastly is the star type.

Stay Cable layout can also be further classify into 3 different types,

- Side-spar

- Cantilever-spar

- Parallel-spar

The earliest cable stayed bridge dates back to Sweden’s Strömsund Bridge built in 1956 with a main span of 182 meters. Half a century later, the rapid development of stay cable technology had seen the construction of 200 over cable stayed bridges with span of 200 meters or more. And 100 over cable stayed bridges with span of 400 meters and more. Examples of these mega cable stayed bridges are, France’s Pont de Normandie Bridge in Normandy with span of 856 meters, China’s Sutong Bridge in Jiangsu Province with span of 1088 meters, and Russia’s Russky Bridge in Vladivostok with span of 1104 meters. Currently, Russky Bridge is the largest cable stayed bridge in the world.

Cable stayed bridge is one of the most prominent application for stay cable system. Its span distance is a lot further than traditional bridge, which is typically about 40 – 50 meters. And there are also a few types of tower to cable stayed bridge, namely

- Single ‘I’ type

- Double “I’ type

- ‘A’ type

- ‘Y’ type

- ‘H’ type

- Portal type

- Diamond type

And these bridge towers can be constructed by reinforced concrete or steel structure. The usage of PC wire in stay cable had also been transformed to the usage of PC strand. And this transformation has further increased the efficiency of stay cable fabrication and installation. Epoxy coated PC strand further increased the lifespan of these stay cable and this innovation greatly reduces the maintenance and cost that comes after the construction of these bridges.

Stay cable utilizes the ‘self-anchorage’ concept, similar to post tensioning way of anchorage. However in recent years, there is a trend of self-anchoring stay cable, coupled with ground anchor technology. Example is Barrios de Luna Bridge in Span with span of 440 meters. The usage of ground anchor technology into stay cable system originated from the concept of suspension bridge. The two end of the main cable of a suspension bridge is normally split up into many smaller bundle of cables which are driven into the ground. And it is these small bundles of cables anchored into the ground (that is why the name ‘ground anchor’) that holds the load of the whole bridge deck. By incorporating ground anchor technology into cable stayed bridge, it allows the stay cable positioning on the deck to be more optimum in relative to the geographical situation of the bridge. Making the stay cable configuration more versatile and also with reduced usage of material.

In general terms, cable stayed bridges is most suitable for span distance of 300 – 1000 meters. And it is more prominent when cable stay bridge is in comparison to suspension bridge under this range. Renowned structure engineer and bridge designer, Mr Fritz Leonhardt, even commented that cable stayed bridge of span 1400 meters uses 50% less in high tensile strength PC wire as compared to suspension bridge. And with a 30% reduction in construction cost.

Over the last 50 years, the development of stay cable technology has advanced by leaps and bounds. And it is in the human race that we will continue to push for cable stayed bridge to have

- span distance above 1000 meters

- more efficient and lighter structures

- improve corrosion protection to stay cable

- more flexibility and versatility to stay cable features

- safer and greater control during stay cable installation

- and more influence to stay cable behavior under adverse environment

Here are some production photos of our stay cable system.