Product Brochure

Prestressed Concrete

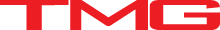

Stress Anchors

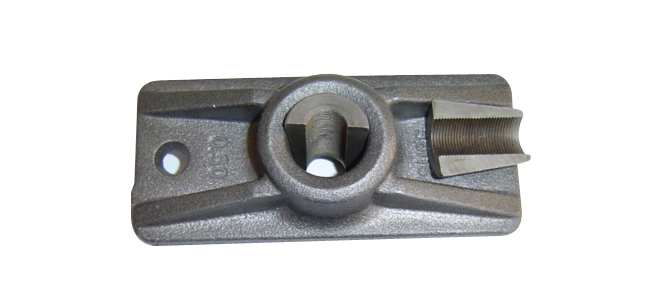

Stress Anchors (also commonly known as Live Anchors) is the most widely used form of anchors in prestressed concrete works. It consists of Anchor, Casting, Wedge and Bursting Reinforcement. It is most commonly found in bonded post tensioning using PC strand as tendons in prestressed concrete structure and rock/soil anchoring structure.

TMG Stress Anchors ranges from 1 to 55 strands, with PC strand size of 9.53mm to 21.80mm.

One of the world’s most widely used construction materials for bridge and building is prestressed concrete. Prestressed concrete is well known to be reliable and also durable. Primarily due to it’s unique characteristics and predictable nature. Its contribution to the construction industry is far and wide. Prestressed concrete presence in foundations, bridges, buildings, towers, tanks, power plants, drilling rigs, etc. has made it the predominant material and technique in an enormous array of structural applications. Owners and developers preference on prestressed concrete is obvious. The advantages includes :

- Under the conditions of live load, prestressed concrete is relatively free from tensile stresses because of the active reinforcing carried out by the prestressed tendon. Hence possibility of deflection and cracking is minimal.

- Eccentric prestressing can be achieved and this is used to counter-balance the effect of dead load (eg. water tank).

- Because of compressive stresses applied by the prestressing force, prestressed concrete has better resistance to shear forces. Leading to lower maintenance cost.

- Reduced material usage and lower superstructure construction cost.

- Reduction in superstructure weight will also bring along the benefits of lesser foundation needed.

- High-rise building with thinner floor slab. This can translate to additional floors to the same building height. In other words, increased in plot ratio.

- Increase span lengths and thus the reduction of columns. This result in fewer joints as well.

- Lesser joints will mean lower maintenance costs on the long run. Because joints are major weakness in most concrete structures.

- More usable free spaces, especially for warehouses and parking garages.

- The elimination of cracks will improve the reliability and durability of prestressed concrete structures under aggressive and corrosive environmental conditions.

- The fatigue strength of prestressed concrete structure is also better as PC strand has very low relaxation characteristic. And this is especially recommended for dynamically loaded structures.

- Prestressed concrete structure deflects more than conventional reinforced concrete, thus giving ample warning before collapse. And this is an improved safety factor.

Slab On Grade (unbounded) is also increasingly popular with industrial structures where joints are the major weakness in these concrete structures. Temperature variations, high traffic, heavy loads and vehicle wheels abrasion are major factors contributing to cracks, deformations and curling in these concrete structures. These failures increases maintenance cost and also reduces productivity.

TMG unbounded post tensioning work for Slab On Grade can eliminate these problems, and it can also optimizes the overall cost to the client for the entire structure.

It is commonly found in (not limited to) warehouses & goods distribution centers, manufacturing plants, airport / seaport & rail container terminals, floor bases of water / sewage tanks, aircraft hangers, heavy vehicle workshops / parks, skating rings, basketball / tennis courts etc.

TMG Stress Anchors provides users with a safe and reliable system, it is also highly efficient, and thus providing users trouble-free stressing, coupled with TMG Stressing Jack.